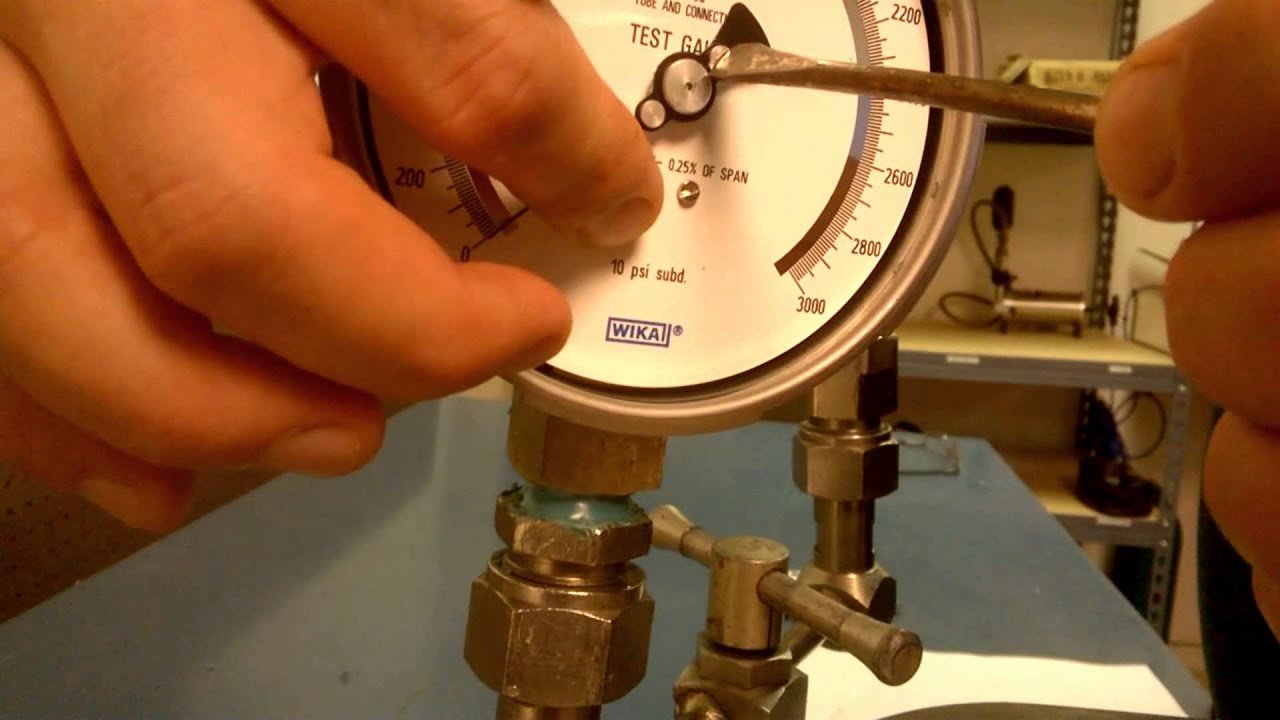

In order to keep gauges and other measurement instruments as accurate as possible, calibrations are absolutely necessary. Standard alignments are important to guarantee that these gadgets give solid and exact readings. Be that as it may, deciding the recurrence at which check adjustments ought to be performed relies upon a few elements, like industry guidelines, instrument use, and natural circumstances. The gage calibration is a critical process that ensures the accuracy and reliability of measurement instruments.

One of the essential contemplations in deciding the alignment recurrence is consistence with industry guidelines. The calibration intervals for gauges are established by stringent quality control standards in a number of industries, including aerospace, pharmaceuticals, and manufacturing. Specific timeframes, such as annual, semi-annual, or quarterly calibrations, are frequently outlined in these regulations. Maintaining compliance and meeting regulatory requirements necessitate adhering to these guidelines.

The frequency and conditions under which gauges are used are two additional important considerations. Calibrations of gauges may be needed more frequently in harsh environments or those that see a lot of use. In order to guarantee accurate measurements, gauges used in high-pressure or high-temperature applications, for example, may require more frequent calibrations. In a similar vein, gauges that are used in critical applications or safety-critical systems may also need to be calibrated more frequently to reduce the possibility of risks.

Notwithstanding industry guidelines and use conditions, the exactness prerequisites of the particular application should likewise be considered. In order to maintain the desired level of precision, some applications may require more frequent calibrations due to stringent accuracy requirements. Then again, applications with less basic estimation prerequisites might take into consideration longer alignment stretches.

Moreover, it is critical to consider the verifiable exhibition of checks while deciding adjustment frequencies. Observing the security and float of measures over the long run can assist with distinguishing any deviations from their unique exactness. To correct or compensate for these variations, it may be necessary to calibrate the gauge more frequently if it exhibits signs of instability or drift.

In the end, a comprehensive analysis of industry standards, instrument usage, environmental conditions, accuracy requirements, and previous performance ought to serve as the foundation for determining the frequency of calibration. To ensure that the gage calibration intervals are appropriate and in accordance with the necessary guidelines, it is recommended to consult industry professionals, calibration service providers, and relevant standards organizations.