Especially like vehicle lines, the beginning stages and history of power transmission belts are lost in the mists of time. While we acknowledge that the Babylonians and Assyrians included chains and cups for water-drawing machines, the earliest notification of a mechanical belt drive with a pulley machine is in a Chinese text from 15 BCE. This depicts the state of affairs set up to breeze silk fibers onto bobbins for weaver’s vans. Something like 1,000 years afterward, when the primary point by point robotized turning wheel was recorded, again in China, it relied upon a belt drive. I view this as enchanting – because the material business is home to different applications for power correas de transmisión today.

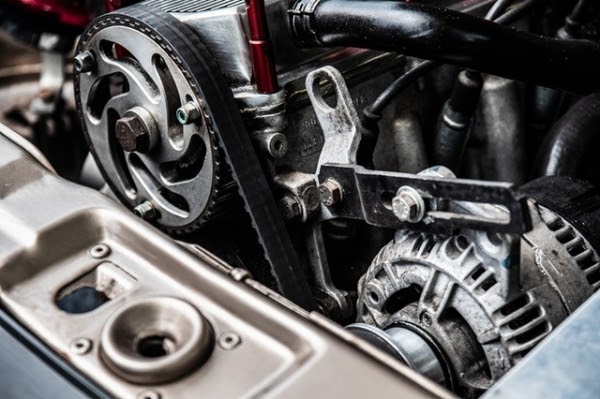

Power transmission belts run true to form and subtly, helping with shielding equipment from over-trouble and staying and safeguarding motors and direction against load changes. They need outside help and are incredibly viable (up to 98%). As you expect, the materials used for power correas de transmisión have changed throughout the long haul. While beforehand, level belts were regularly made of cowhide, during the nineteenth century, they also used cotton, hemp, flax, or even wire ropes.

Power transmission with calfskin belts remained a notable response for a seriously significant time frame. Calfskin belts were the state-of-the-art reply for compelling power transmission even close to the beginning of the 20th 100 years. You can see this in pictures that show, for example, a studio with a fundamentally driving shaft on the rooftop, with handling machines, machines, exhausting machines, and other stuff running off, not entirely set in stone by calfskin belts. Power transmission belts have found various new and huge purposes today.

Also, remembering that they continue to accept a fundamental part of present-day machine plan, they are less evident than beforehand.

As a rule, they are defended by the machine layout and play out their endeavor undercover. The going with models shows the capacities of this surprising machine part in different organizations: Power transmission belts for punching machines, presses, etc., have a tough spot since they need to send very high loads. They moreover need to absorb shocks, for occurrence, over-troubles, to defend other machine parts like motors and course. Power transmission belts drive the live rollers in the appointment and bundle orchestrating centers. These belts make a binding obligation to your online orders’ speedy and advantageous transport.